Concrete Contractors

Estimate, Plan and Manage Pours Better with Tekla BIM Software

Tekla 2025 New Features

Estimate, Plan and Manage Pours Better with Tekla BIM Software

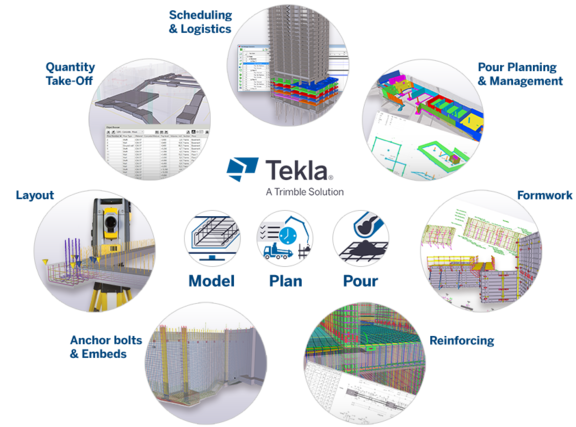

Estimate, plan and manage concrete pours better with quality information and constructible models purpose-built for the needs of concrete construction. Tekla software allows concrete contractors to reduce their risks, improve productivity and ensure smooth progress on site with the unique information management tools and constructible concrete models the tool can offer.

From preconstruction to on-site management, Tekla offers a complete solution for concrete contractors. With Tekla’s ability to handle pours and manage pour-related information effectively, the software is an essential tool for improving concrete pour planning and management on site.

With Tekla you can

- Improve estimates and schedules

- Automate quantity take offs and effectively manage information

- Improve pour planning and on site productivity

- Ensure constructability and solve issues early

- Follow up progress, coordinate and manage teams effectively

- Manage changes easily

- Reduce risks from preconstruction to pour at the office and on site

Concrete modeling with BIM software

3D Concrete Modeling Purpose-built for Construction Needs

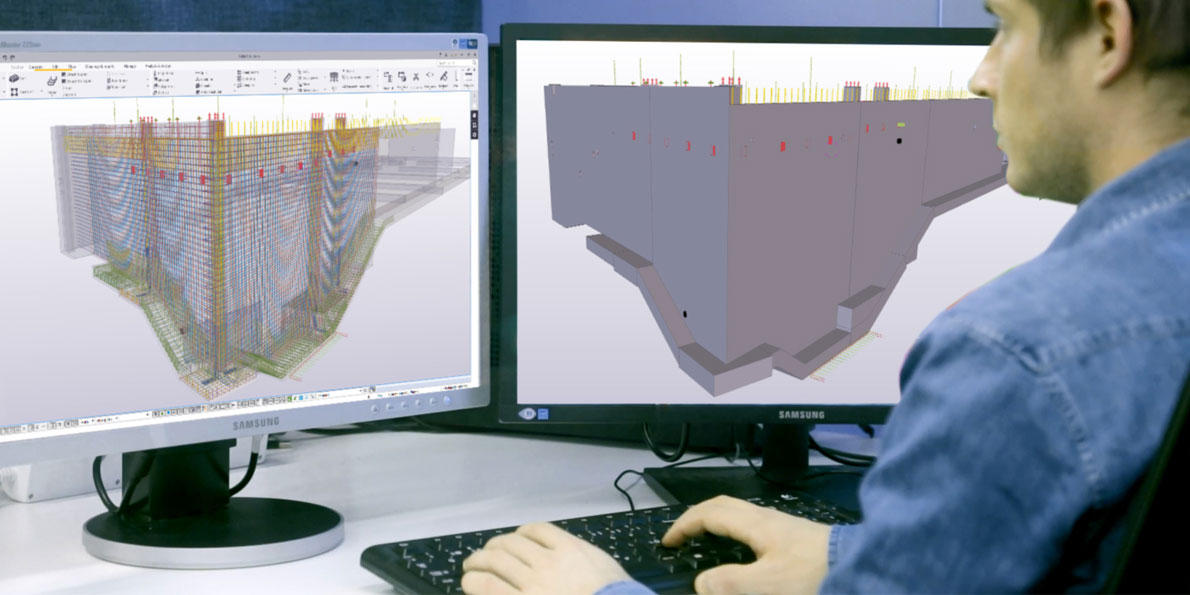

Accurate, constructible concrete models purpose built to meet the complex needs of concrete construction allow contractors to reduce risks, save time at the office and on site and improve the pour productivity on site. With the reliable information and tools provided, you can plan and manage the concrete construction process better.

With Tekla Structures you can create construction-ready concrete models to really build with. Coordinate concrete and rebar work and ensure constructability, foresee possible challenges and simulate your job virtually and turn the design successfully into concrete reality.

Tekla models are complete with accurate pours, detailed rebar, embeds and formwork. Visual 3D model information is easily available for measuring, reporting and managing projects. Using the intuitive information management tools you can automate tedious, manual material quantification and information management tasks. You can identify and accommodate to project changes quickly with the model.

Fast start with efficient reference handling

Easy tools for quick 3D concrete modeling

Constructible 3D models you can really build with

Understand your structure and ensure smooth progress on site

Create drawings, rebar schedules and material reports automatically

With Tekla you can

- Create constructible concrete models quickly and easily

- Plan and manage pours effectively with the unique, intuitive tools

- Ensure constructability, detect clashes and find and fix problems early

- Save time and prevent errors with reliable material quantification

- Generate drawings directly from the model and report in real-time

- Visualize information and communicate and coordinate effectively

- Manage all project changes easily

Model-based Quantity Takeoff

Quick, reliable model-based quantity takeoff software

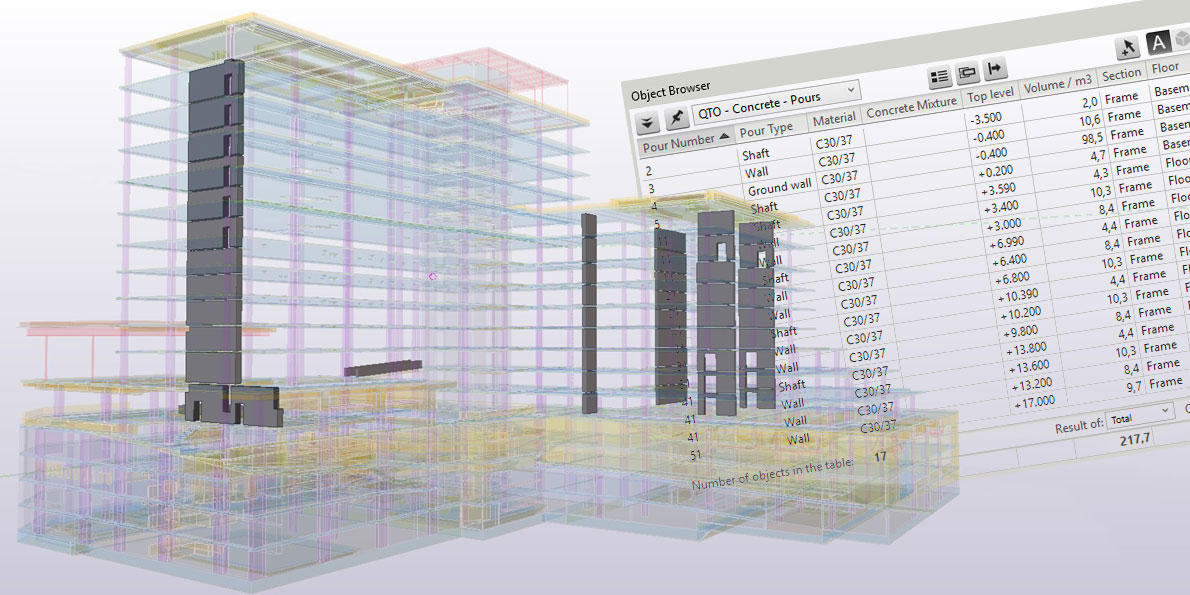

Save time in material quantification, avoid the pains from incomplete and uncoordinated drawings and reduce the risks of incorrect quantities from preconstruction to site management with a constructible model.

With Tekla models, you can quickly generate quality information in order to be confident of your numbers and bid. Prepare to pour and run your construction operations efficiently with a clear understanding of your projects, and benefiting from the easy access to up-to-date, consistent and construction-ready quantities.

Using flexible tools you can automate the tedious, manual material quantification and information management tasks. Accurate models allows you to visualize information and generate reliable on-demand reports for concrete, rebar, embeds and formwork with accurate information complete with logistics and material attributes.

Achieve reliable estimates and schedules for material quantity takeoffs

Easy access to quantities and on-demand reporting in real time

Organize your project information on the fly

Visualize take offs and communicate clearly

With Tekla you can

- Organize your project information on the fly

- Be sure of your bid with better estimates and schedules

- Enjoy an easy access to reliable quantities and find relevant information quickly

- Quantify materials in real time

- Create on-demand reports with precise, consistent information

- Communicate clearly with others using the 3D model, on desktop and mobile

- Identify and accommodate project changes quickly

Concrete Pour Planning and Coordination

With Tekla concrete pouring plan you can efficiently manage and deliver succesful concrete pours everytime

Improve your productivity in the office and on site, save time in pour planning and take offs, and pour the concrete successfully. Tekla allows you to model and develop an accurate concrete pouring plan to manage and coordinate pours on site accurately and efficiently.

With Tekla's unique pour handling functionalities concrete contractors can create concrete pour plans that streamline their work from preconstruction to pour. Reliable information in constructible model and efficient information management tools in Tekla software allow automating material quantification and planning for successful pours.

Accurate 3D concrete models are complete with areas, volumes, required mix information, rebar types, embeds, formwork and more. Practical pour sequencing and scheduling tools, 3D visualizations and instant access to pour-specific quantities mean that you can budget and allocate resources better, monitor progress easily, coordinate your work and report in real time. You can create lift drawings, pour plans and layouts automatically from the model. Communication with other project stakeholders is clear with easy to understand 3D information.

Intelligent concrete model result in a fast and flexible concrete pouring plan

Define pours accurately with easy pour break tools

Easy access to required quantities and on-demand reporting

Create lift drawings and pour plans

Monitor progress and coordinate projects effectively

With Tekla you can

- Streamline your work and improve productivity in the office and on site

- Plan and manage pours efficiently with the constructible concrete model

- Create clear lift drawings, pour plans and layouts automatically

- Utilize the consistent, comprehensive information in the model, on desktop and mobile

- Track progress and report in real time

- Visualize sequences and project status and communicate clearly in 3D

- Manage all project changes easily

Concrete formwork with Tekla

Next level formwork construction by better planning, quantification and coordination

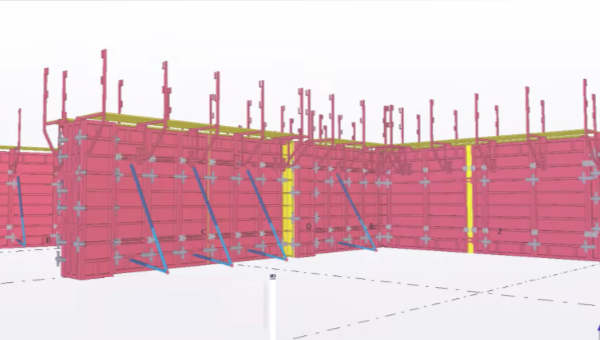

Tekla understands how concrete is poured. With its unique pour handling functionalities and ability to manage all pour-related information effectively, Tekla users can successfully estimate, plan and manage formwork operations on site.

Formwork is one of the most time-consuming parts of cast-in-place concrete construction, which makes good planning essential. With Tekla, you can speed up formwork planning by automating material quantification and drawing creation. Contractors can save time, prevent mistakes and streamline formwork operations on site thanks to better visualization, coordination and communication that constructible formwork models make possible.

Using pour and concrete geometry in the Tekla model with interactive and automated tools makes creating realistic formwork models quick and easy. This brings great accuracy and efficiency for the concrete contractors who can plan and optimize their formwork operations, and manage the related information more easily in order to successfully prepare to pour concrete on site.

Automated concrete formwork area calculations

Plan placing and model constructible formwork quickly and easily

Instant material quantification and drawings directly from the model

Use ready-made components or create your own

Communicate your formwork requirements clearly

With Tekla you can

- Estimate and plan better with an instant access to required formwork areas

- Streamline formwork planning, management and coordination on site

- Automate material quantification, report in real time and manage all information more easily

- Prevent mistakes and ensure smooth progress on site when preparing to pour

- Create clear formwork plans and drawings directly from model

- Communicate clearly with others using the 3D model

- Manage all changes easily

See Tekla in use

Construction Layout with Tekla

Link your concrete layout models to reality with Tekla concrete layout tools

Because time is money in construction, efficiency contributes to profitability. Field layout is an essential task where accuracy is necessary, but when executed with drawings and tape measure it can be, like many traditional construction tasks, time-consuming and prone to errors.

Total stations increase productivity of the layout process and by integrating accurate Tekla models to Trimble’s layout tools, you can utilize flexibly the exact location information in the virtual building and make layout tasks faster and more exact.

Everything you want to measure on site can be included in your constructible model. When your structure fits in the model, you know it fits in the built reality. With Tekla you can automatically generate and group layout points from the accurate model. Tekla software and total stations from Trimble integrate seamlessly, but commitment to open BIM means that a variety of devices is supported.

After the pour is done, you can link the field information back to the model, verify the accuracy of your work, and make any necessary changes so that your model matches the built reality. Ensure smooth progress on site with up-to-date, consistent information and documents created from constructible Tekla model.

Software made to generate concrete layout data fast and flexibly

Transfer point data from virtual model to field layout solutions

Save money on site with accurate, one person layout

Transfer updates from the site back to model and ensure smooth progress

Communicate your formwork requirements clearly

With Tekla construction layout software you will

- Reduce delays through better communication between the field and office

- Create and group layout points automatically

- Exchange exact point data between the model and field layout devices

- Visualize as-built layout data from the site in your virtual building and find possible needs for design changes

- Manage changes easily and keep project documents and information up-to-date

- Communicate clearly with others using the 3D model, on desktop and mobile

- Ensure constructibility with accurate model and progress smoothly on site

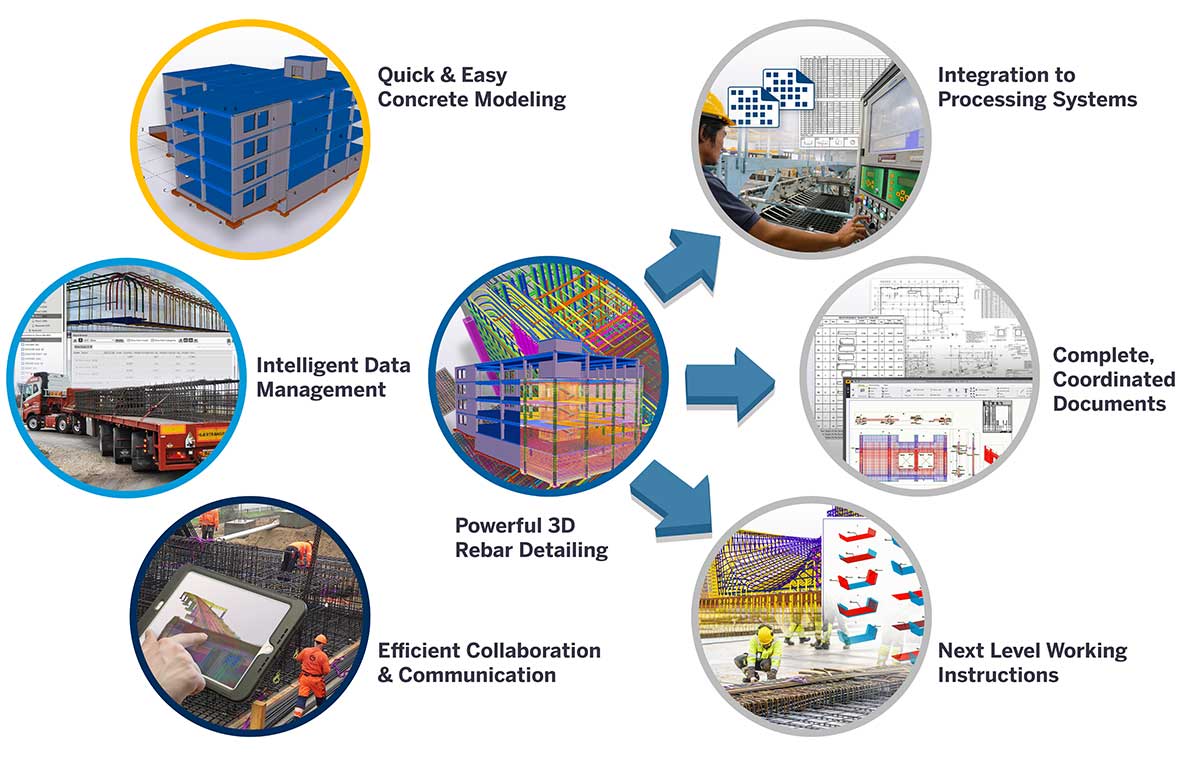

The Most Advanced BIM Software for Rebar Detailing and Reinforced Concrete Construction

Working with Tekla software is a smarter, more efficient way to do rebar detailing and fabrication. Improved design communication, coordination and information transfer enables faster rebar assembly and more productive construction of reinforced concrete structures.

The most powerful, yet straightforward, 3D modeling environment automates repetitive rebar detailing and documentation tasks. With intuitive management tools the construction-quality information is always easily at hand for reporting and material handling. You can automatically export data to rebar MES software and cut-and-bend and mesh welding systems. Easy to understand rebar assembly guides with 3D visualizations reduce RFIs, improve quality and make prefabrication and rebar placing on site more efficient.

With Tekla you can

- Detail any rebar structure in 3D, regardless of size and complexity

- Number rebar automatically and generate all documents directly from a model

- Prevent detailing, documentation and coordination errors

- Save time and prevent human errors in data input to rebar processing systems

- Adapt to project changes effectively

- Find, use, report and transfer information efficiently according to your process needs

- Drive efficiency and quality in fabrication and in the field